China has been the world's rubbish dump for a long time. It recycled waste from all over the world, including lots of plastic from Belgian companies. Suddenly, China says it doesn't want our waste anymore. What do we do now?

‘Le plastique c’est fantastique’, declared the French pop group Elmer Food Beat. China, on the other hand is saying 'no, thank you' to plastic. It doesn't want our waste anymore.

What's happening? For many years, lots of waste from the West was shipped to China. Container ships full of plastic items that were 'Made in China' arrived at our ports. The emptied containers were then filled with plastic and other waste, which made the return trip very cheap. Over in the Far East, our waste was recycled and the recycled materials were used by Chinese companies to make new products for Western consumers. The global economy at its best, you might say.

Now, China is sick of being the world's rubbish bin. It wants to improve its environment and focus on more modern, high-quality economic activities and recycling other people's waste doesn't fit into this strategy. Last summer, the country informed the World Trade Organisation that it doesn't want our waste anymore. Less than six months later, the border was closed to 24 waste streams. It was a bolt from the blue.

What are the implications? They're immense. Take plastic, for example. Last year, China imported 7.3 million tonnes of plastics. That's around half of the global plastic waste. All these exporters must now look for other solutions. For our country, the biggest challenge lies with industrial plastic waste, explains Ingrid Bouchez, communications manager at VAL-I-PAC.

Ingrid Bouchez: "Belgium recycles lots of waste on its own soil or in neighbouring countries. We also process our household plastic waste almost entirely locally. The problem primarily lies with packaging films and other industrial plastic waste. This waste was largely sent to China, until recently."

Now that China has closed its doors, the plastic is piling up. Incineration is prohibited, as sorted waste is not allowed to be sent to incineration ovens. In Belgium, there are companies that recycle plastic and use it to make furniture and other new products. But that only occurs on a limited scale and so it's not a solution to the fast-growing plastic mountain. Jan Verheyen, spokesperson for OVAM, calls it a wake-up call.

Jan Verheyen: "Hopefully the new Chinese situation will lead us to adopt a new approach. We must urgently build extra processing capacity on a local scale and close the plastic circle by making new products with recycled plastics."

The new processing capacity will not appear overnight. China's decision was totally unexpected and the deadline is very short.

Ingrid Bouchez: "The sector is frantically looking for solutions. Creating extra capacity is the most urgent challenge. But the need for ecodesign is even more important: the packaging that comes on the market must be designed to be easier to recycle and result in higher quality recycled materials. Furthermore, extra capacity goes hand in hand with encouraging manufacturers of plastic packaging material to use recycled plastic to make new plastics."

It all comes down to money: making new plastic using recycled plastic is usually more expensive than making plastic using petroleum.

18.07.2018

Innovative heating system in Ghent

In Ghent, a sustainable romance is blossoming. The company Christeyns will heat a new residential area with its residual heat. In return, the residents will show their gratitude by giving the company their purified waste water.

In the coming years, a new residential area will be built at Oude Dokken in Ghent, a former port area near Dampoort Station, with 400 homes, a school and a sports hall. There, they will implement an innovative heating system. The buildings will be heated through a unique combination of techniques. All of the homes will be connected to a heating network, which will heat the entire area. Residents will not have their own individual heating systems, but instead will each have a heat exchanger that extracts heat from the collective system. No fuel, gas, electricity or wood is required.

How does it work? A third of the heat is produced by the families themselves. The waste water from their vacuum toilets and ground kitchen waste is converted into biogas in a fermentation tank. This gas is used to heat the water. The other two-thirds of the required heat is provided by the nearby Christeyns. This company is a world player in specific niches: the industrial cleaning and disinfection of hospital and hotel linen and the purification of installations for food and beverage companies.

Jef Wittouck (Managing Director of Christeyns): "In particular, the production in our oleochemical department creates a lot of residual heat. Currently, this heat largely goes to waste. The small amount of waste water we produce is collected in a cooled state by an external partner and processed elsewhere. In the future, this residual heat will be pumped through underground pipes to the new residential area. It's good for the area, but also for us: our cooling installations won't have to run as intensively.

Sustainable...and not overly expensive

The love is mutual. The sanitary sewage from the new residential area (around 30,000 m3) won't flow into the sewers. First, the heat will be extracted and returned to the heating network. Then the water will be collected in the area, purified and sent to Christeyns through pipes.

Jef Wittouck: "In our production processes, we use city and well water which is purified and demineralised through reverse osmosis. If the residential area can purify its waste water and deliver good quality water, we can also use it as process water. It's not an easy feat. We have a lot of experience with purifying waste water. It's not an exact science. It's difficult to predict how well a purification technique will work with a certain kind of waste water. Sometimes you need a range of techniques. We hope that the exchange will be mutual. If the plan works, we can expand our capacity without having to invest in extra filter systems."

The economic aspect certainly plays a role, according to Christeyns.

Jef Wittouck: "We are investing in this project because we want to anchor our company in the local, social environment and because we want to be sustainable. However, it's only a win-win situation if it's financially viable. For example, we are now considering purchasing an installation for cogeneration. This way, we can rely less on our boilers and produce cheaper electricity. This would result in more residual heat, but maybe we can also transfer that to the collective heating network in the residential area."

It also has to make financial sense for the families living in the new residential area. The system requires an investment of 4 million euros and is managed by the sustainability cooperative DuCoop. They guarantee the residents competitive prices and want to invest in 100% green energy that is generated on-site, as far as possible, and stored using battery technology. The area will also have a network of electric charging stations for cars and bicycles.

Where's the sustainable party?!

Here's a nice idea for a company bash: make everything sustainable and serve your guests beer made from malt, hops, yeast and....waste water! Bio-engineer and brewer Denis De Wilde (www.dewildebrouwers.be) has already succeeded in making brews with his own waste water, and even with sewage water. One of those beers has the very fitting name of 'From Sewer To Brewer'.

Denis De Wilde: "Using techniques such as ultra filtration and reverse osmosis, you can purify and reuse a large portion of waste water. This is no superfluous luxury as ground water is decreasing, as are freshwater reserves. We must be careful with our natural resources. Soon, we will start using filtered rainwater. Our roof is 2,000 m2, so it's a large source of rainwater that we can purify and use in our brews."

In order to minimise your party's footprint, consider hiring Boombar (www.boombar.be). This mobile and modular bar system is a consolidation of knowledge and various techniques regarding sustainable energy, cooling, heating and water consumption. Make your pint a guilt-free one.

25.07.2018

Creative uses for construction waste

Most construction waste is recycled in one way or another. However, sometimes direct reuse is possible and valuable heritage can be given a second life.

Construction and demolition waste accounts for 20% of our total waste. Over 90% is reused. Sometimes via high-quality recycling, and sometimes via 'downcycling'. In the latter case, the rubble is ground up and used as granular material for road foundations. Some companies have found unique ways of taking demolition waste and fully or partially reusing it, rather than recycling it.

Schoenen Torfs are proud of 'Ten Afval'. It's a recycling project that first and foremost benefits their employees. When the company renovates one of its seventy shops, the employees are free to dismantle and empty the interior themselves. Furniture, flooring, lighting, decorations: employees can take all of it home with them.

"As a result of 'Ten Afval', the materials that are removed from the waste stream are given a second life," explains manager Wouter Torfs in Trends magazine. "It's a real win-win situation: it's better for the environment, we don't need to hire a contractor or pay landfill costs, and it keeps our employees happy."

The golden ceiling

Rotor Deconstruction has made reusing old construction materials in new projects its core business. For each demolition, this waste processing company assesses which materials are valuable enough to finance the dismantling. An excellent example of this process is the dismantling of the BNP Paribas Fortis building in Ravenstein. The building dated from 1971. The counters, strongroom, lifts and executive offices of the former Generale Bank were designed by the famous Belgian interior architect and furniture designer, Jules Wabbes.

The old 'golden ceiling' that Wabbes designed - false ceilings made from aluminium coated in gold-coloured lacquer - was repurposed in many different ways. Plusofficearchitects reused parts of the ceiling in the new auditorium of the municipal library in Sint-Pieters-Woluwe. Another piece of the golden ceiling is now hanging in Emilie Pharmacy in Schaarbeek, which architect Nathalie De Leeuw renovated for pharmacist Saïd Bounouch. The architect suggested using as many reclaimed materials as possible and went with Bounouch to browse the Rotor showroom. The gold-lacquered aluminium grille is now the focal point of the pharmacy. In the entrance, a piece of the bank's old granite floor and a few panels with photo prints by interior architect and designer Christophe Gevers were reclaimed. This gave these culturally valuable pieces of Brussels' history a new place and function in the city. Rotor Deconstruction was awarded the OVAM Ecodesign Award PRO for this project.

27.06.2018

Sorting plastics

The three regions have similar sorting obligations. However, the timing of the introduction of these rules differs. Wallonia has been sorting plastics since 2016, Flanders will start on 1 June, but Brussels has no plans as yet.

Medium-sized and large companies are responsible for their waste streams. They enter into contracts with recognised waste collectors who collect residual waste and many other types of waste. The contract states which waste streams are produced as a result of the company's operations and how they will be sorted and collected.

Which types of waste must companies sort? There are quite a few:

- small hazardous waste arising from company activities

- glass waste

- paper and cardboard waste

- used animal and plant oils and fats

- green waste

- textile waste

- discarded electrical and electronic equipment

- waste tyres

- debris

- processed oil

- hazardous waste

- waste containing asbestos cement

- discarded equipment and containers that contain ozone damaging substances or fluorinated greenhouse gasses

- waste agricultural films

- discarded batteries and chargers

- wood waste

- metal waste

- PMD (Plastic bottles, Metal packaging and Drinks cartons) waste

And now plastics

In Wallonia, companies have been obliged to sort their plastic packaging since 1 January 2016. In Brussels, it's not yet mandatory. Companies in Flanders must begin sorting three types of plastic as of 1 June 2018: recyclable hard plastics, expanded polystyrene (clean polystyrene packaging with a bead structure, also known as 'Styrofoam') and films that are used as secondary or tertiary packaging.

The reason for this new measure is simple: plastics, when incinerated with residual waste, create considerably more air and water pollution than when they are properly recycled. The emissions prevented more than compensate for the emissions produced during plastic collection. However, the cost can be off-putting.

Jan Verheyen (spokesperson for OVAM): "A feasibility study showed that it's expensive for companies to sort small amounts of plastic and have them collected separately. For companies with little company waste, it can be better to organise the collection via a collective collection or to take certain types of plastic waste to a collection point or municipal recycling park themselves. There are pilot projects testing collective collection points on industrial sites."

Financial incentives

As a rule, it's financially advantageous to separate as much recyclable waste as possible from the company residual waste. VAL-I-PAC encourages recycling by offering premiums to companies that sort and recycle their company packaging waste. However, there are some conditions: the waste must have been produced on Belgian territory and be sorted, after which it must be collected by a VAL-I-PAC recognised waste collector and recycled.

Ingrid Bouchez (communications manager at VAL-I-PAC): "Our premiums encourage companies to sort all types of materials, but, in particular, wood and plastic. Previously, many companies gave their wood waste to employees, for their stoves or fireplaces, or waste collectors took it to be used for energy. However, reuse or recycling is preferred over incineration."

Three types of premiums

VAL-I-PAC's premiums do not compensate for the logistics bill you will receive from your waste collector, but they do cover additional expenses, such as container hire. There are three types of premiums:

- a one-off initial premium of 100 euros for companies that are using a container to sort a certain type of packaging waste for the first time.

- a recycling premium for wood packaging waste (10 euros per tonne), plastic packaging waste (30 euros per tonne) and waste from plastic lashing straps (50 euros per tonne).

- a container premium for different types of waste containers, bins and bags.

Companies don't need to submit a request themselves. Your waste collector submits the request to VAL-I-PAC on your behalf. You then receive a letter or email with a unique access code. With this code, you can request the premium via the myCertificate application. The premiums won't make you rich, but they're a nice bonus. You know what they say: every little counts...

More info

- VAL-I-PAC

- www.valipac.be

- www.iksorteerinmijnbedrijf.be (as of 14/05/18)

- OVAM

- Your waste collector

PS:

- For Brussels: Bruxelles Environnement/Leefmilieu Brussel

- For Wallonia: Département du sol et des déchets

21.06.2018

Belgium gets a thumbs up from Mother Earth

It's not all doom and gloom in Belgium. Our companies are world leaders in sorting waste. They sort almost 90% of their company packaging waste. However, there's still room for improvement.

It's not all doom and gloom in Belgium. Our companies are world leaders in sorting waste. They sort almost 90% of their company packaging waste. However, there's still room for improvement.

It seems like the world is turning into a huge rubbish bin. In total, humans produce 1.3 billion tonnes of household waste per year. That's the equivalent of 25,000 Titanic ships filled to the brim. At this pace, by 2025, this mountain of waste will grow to 2.2 billion tonnes. In many countries, waste is still usually buried underground, or worse: dumped into the ocean. Welcome to the big plastic soup. Waste processing counts for 3.4% of CO2 emissions - hardly a negligible percentage. However, this percentage is merely an estimate, as the CO2 emissions produced by waste transport, incineration ovens and food wastage are not included.

One small country is making a courageous effort to combat this global waste stream, at least in terms of sorting and recycling. We're talking about Belgium. Our households have long been role models for other countries. Belgian companies are possibly doing even better, according to data from VAL-I-PAC.

Ingrid Bouchez (communications manager at VAL-I-PAC): "Companies that sell packaged goods must be able to prove to the government that 80% of the packaging waste is recycled. VAL-I-PAC tracks statistics for 7,200 small and large companies. In 2016, 89% of the company packaging waste was recycled. Much of the waste is given a second life: 100% of the paper and cardboard waste, 56% of the plastic waste, 77% of the wood waste and 83% of the metal waste."

The Public Waste Agency of Flanders (OVAM) not only researches company packaging waste, but all the waste that Flemish companies produce. Therefore, their figures indicate a lower rate of recycling. However, Belgians are still doing a lot better than the rest of the world.

Jan Verheyen (spokesperson for OVAM): "Approximately 76% of Flemish company waste is reused or returned to the cycle through recycling or composting, after a maximum of two processing steps. For household waste, it's 70%. Those are great achievements if you compare them to the European average of 50%."

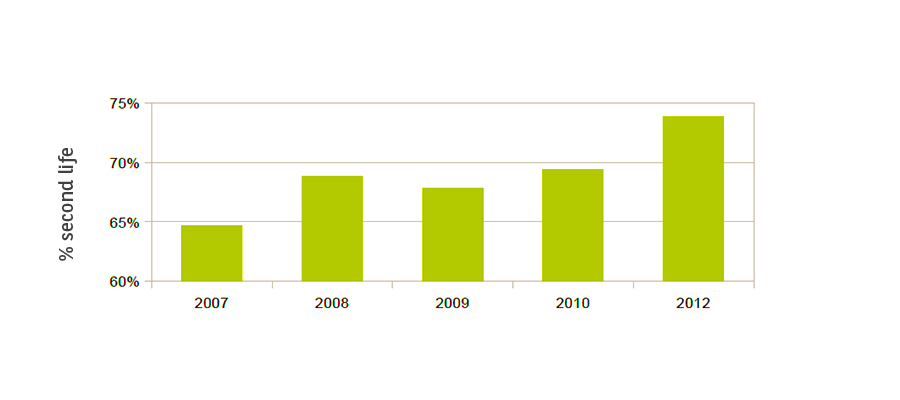

Percentage of waste given a second life after two processing steps (%). Since 2010, the statistics have been obtained from companies every two years (only during even years).

Room for improvement

Before you pop open a bottle of champagne for your colleagues: we're not out of the woods yet. There's always room for improvement. Samples show that a significant amount of recyclable waste still finds its way into the company residual waste.

Ingrid Bouchez: "There are still companies that are not sorting at all, or are not doing it optimally. In particular, the quality of waste streams can be improved. A little more conscientiousness can make all the difference. Keep paper and cardboard dry, prevent paper from becoming contaminated and don't mix waxed paper in with your clean cardboard. Remember to separate different types of plastic: PE shouldn't be sorted with PET or PP."

Jan Verheyen: "Studies show that companies can recycle 20% of their residual waste. These materials are usually films, hard plastics, wood, PMD (Plastic bottles, Metal packaging and Drinks cartons), metals, stone rubble, and paper and cardboard. Hence our ambition: we want to produce 15% less residual waste in Flanders by 2022."

Wallonia, on the other hand, isn't aiming for a percentage, but rather 100,000 tonnes less company residual waste.

Incineration oven or landfill

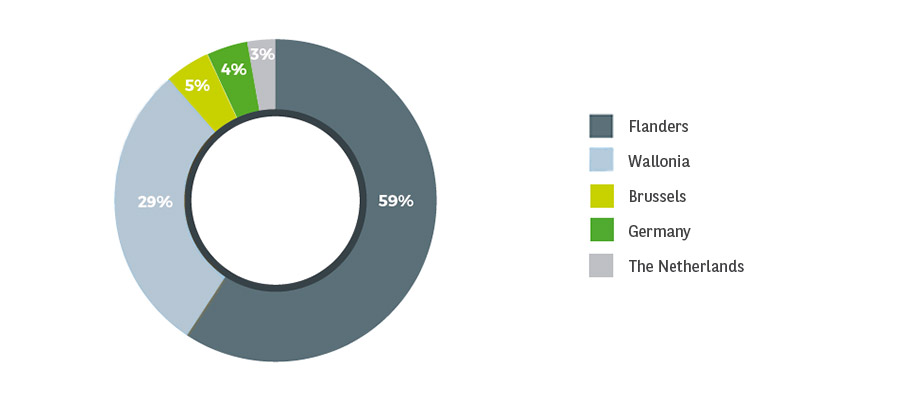

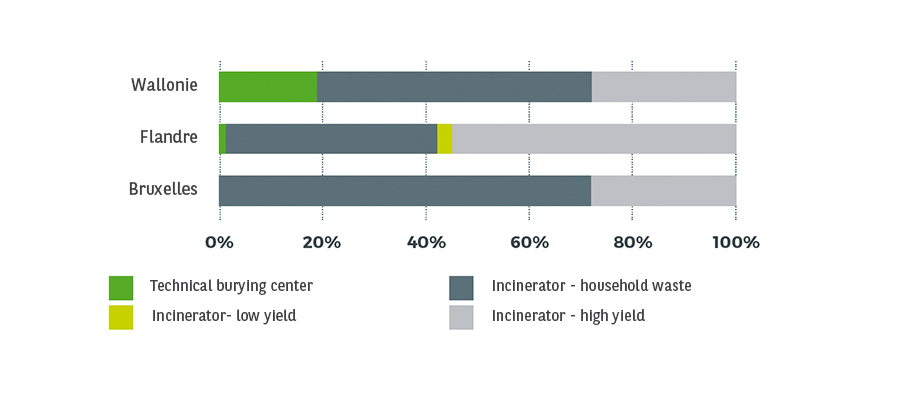

When processing company residual waste, Belgium upholds the 'proximity and self-sufficiency principle': it wants to send as much residual waste as possible to Belgian incineration ovens, so they receive enough material to function properly. Sending residual waste abroad is not prohibited, however it is subject to strict conditions. The result: 93% of residual waste is incinerated in Belgium and the rest is generally sent to the Netherlands and Germany. In Flanders and Brussels, almost all the company residual waste goes to the incinerator. In Wallonia, almost 20% is sent to landfills. The reason is simple: two large landfills have not yet been filled. Once they're full, Belgium will no longer use landfills.

Region where residual waste is processed

Types of residual waste processing per region

More info

VAL-I-PAC

- www.valipac.be

- www.iksorteerinmijnbedrijf.be (as of 14/05/18)